The Impact of Liner and Flute on the Carton

- Khobre Mihan co

- Article

- The Impact of Liner and Flute on the Carton

Table of Content

The Best Flute for Packaging Protection

One of the most important aspects of logistics and transportation is packaging goods. Packaging materials provide the necessary security for items stored for domestic sales or exports, and corrugated cardboard boxes are among the most popular types of packaging. The strength of cardboard boxes is categorized based on the type of flute they have. Flute refers to the corrugated sheets located between the flat sheets of the cardboard box. The construction of the flute helps the cardboard to be more durable and withstand greater pressure. Depending on the number of flute teeth and their height, a higher strength can be created for transporting and storing goods. In the following, we will provide further explanations about the impact of flute and liner on cardboard, and more details about flute and liner. Stay with us at the website of Khobre Mihan Company.What is Liner and Flute on the Carton?

Corrugated cardboard boxes, sheets, and rolls have different layers. In cardboard, one layer is wavy and corrugated, and the other layer is flat and smooth. These layers are placed on top of each other alternately. The wavy and corrugated layer is called flute paper. The number of corrugations in the paper decreases or increases depending on the type of flute. Flutes are available in A, B, C, D, E, and F types. On the other hand, liner paper is a flat sheet of paper that is placed between the flute layers and is more commonly used in the outer layers of a cardboard box for lamination. Flute and liner cardboard are two inseparable parts of cardboard boxes.

The impact of liner and flute on the characteristics of cardboard

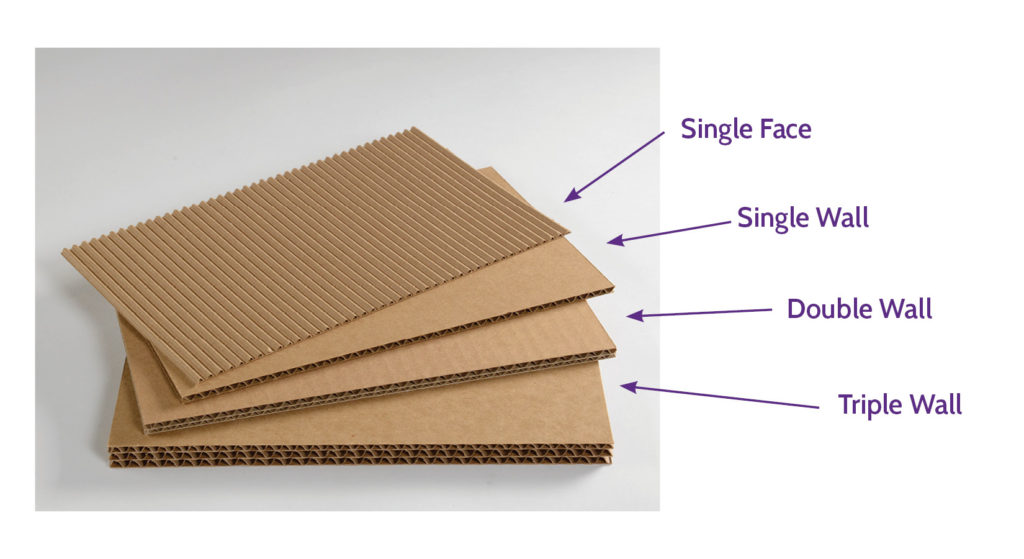

Liner and flute are two inseparable parts of cardboard that can be customized based on the strength and durability of the box. The number of corrugations and the wavy nature of the layers of cardboard sheet increase the strength of the box. The more flutes in the cardboard, the better its impact absorption properties, and the less damage is caused to the goods during transportation and handling. The image below shows the different types of cardboard flutes and their differences.

The difference between E-flute and B-flute cardboard

The main difference between E-flute and B-flute cardboard is the number of flutes per square meter. This number determines the strength of the box and its ability to be printed. While in general, E-flute cardboard has more flutes per square meter, but they are thinner in size. This type of flutes is easy to fold. In addition, E-flute cardboard is the best option for printing, as the size of these cardboard allows them to rotate easily in printers.

B-flute cardboard is suitable for carrying heavier products or goods. This type of cardboard contains fewer flutes per square meter, but the size of the flutes in this type of cardboard box is larger, which also increases their strength. The thickness of the flute limits the space inside the boxes. B-flutes are twice as thick as E-flutes. On the other hand, you should know that B-flutes are also less suitable for printing. The most important advantage of this type of cardboard boxes is their capacity and strength.

To order various types of cardboard boxes with different flutes and high strength and durability, contact the cardboard manufacturing company of Khobre Mihan Company at the following phone number.

Which type of corrugated cardboard box is the strongest?

The strongest type of cardboard is multi-layered cardboard, available in three-ply, five-ply, and seven-ply variations, with strength attributed to the presence of larger flutes. These larger flutes contribute to reinforcing the multi-layered boxes, allowing them to stack without bending. On the other hand, single-ply cardboard, such as corrugated cardboard, is among the more affordable options in the market but lacks the ability to withstand heavy loads. If you are looking for the most durable type of cardboard box, multi-layered cardboard options in three-ply, five-ply, and seven-ply configurations are suitable choices.

We help our customers stand out in the market by providing superior packaging solutions

To achieve this goal, we continuously invest in developing our relationships with our customers so that we can meet the needs of our customers today and tomorrow. The consulting and design team of Mehen’s expert engineers, after hearing the demands of the customers, examined the different ways of packaging the product and then using the valuable experiences of the past and the current knowledge of packaging and the use of new technologies, the most optimal type of packaging examined. provides to consumers. For more information and consultation with us, click on the free consultation button.